Receiving station of the Campo Limpo System in Contenda (PR), managed by inpEV.

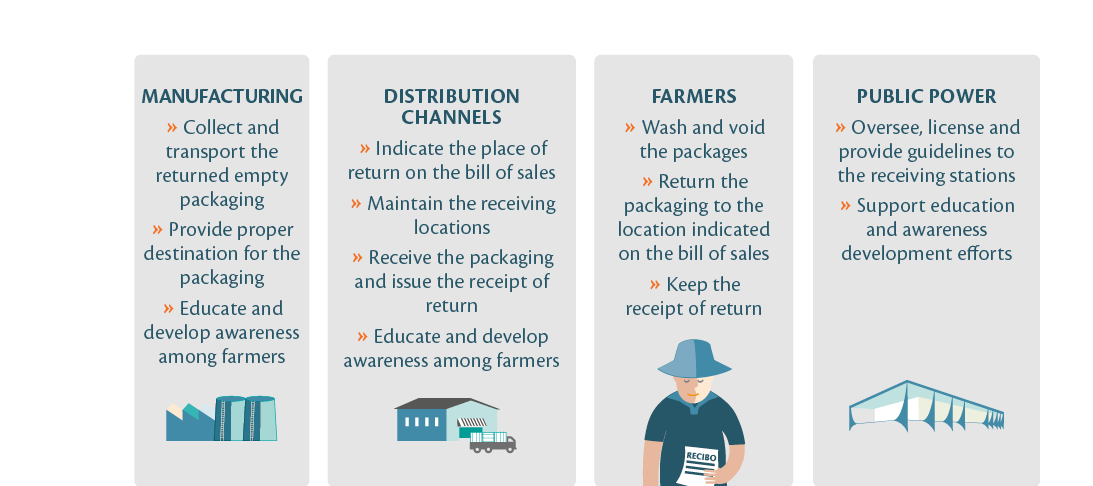

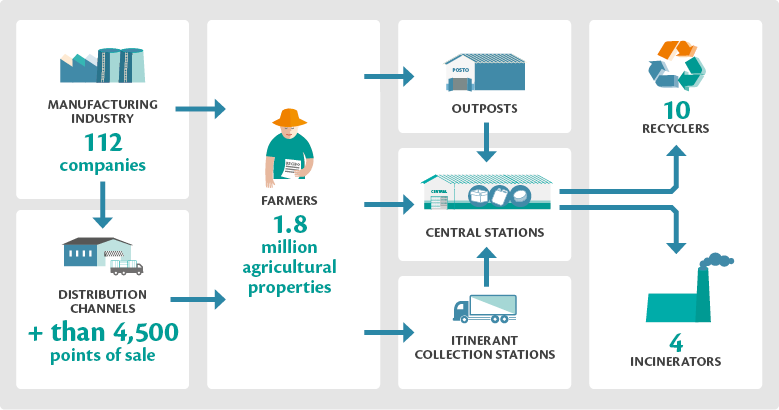

The Campo Limpo System is a Brazilian reverse logistics program for empty crop protection packages or those containing postconsumption crop protection leftover products. It includes the manufacturing industry of these products, the distribution channel, farmers and government, each with its own role and responsibilities defined by legislation, to promote reverse logistics and provide adequate eco-friendly disposal to these packages. The National Institute for Processing Empty Packages (inpEV) is the entity that manages the System and the entire process is regulated by Law 9.074/00 and its regulatory decree 4.074/02.

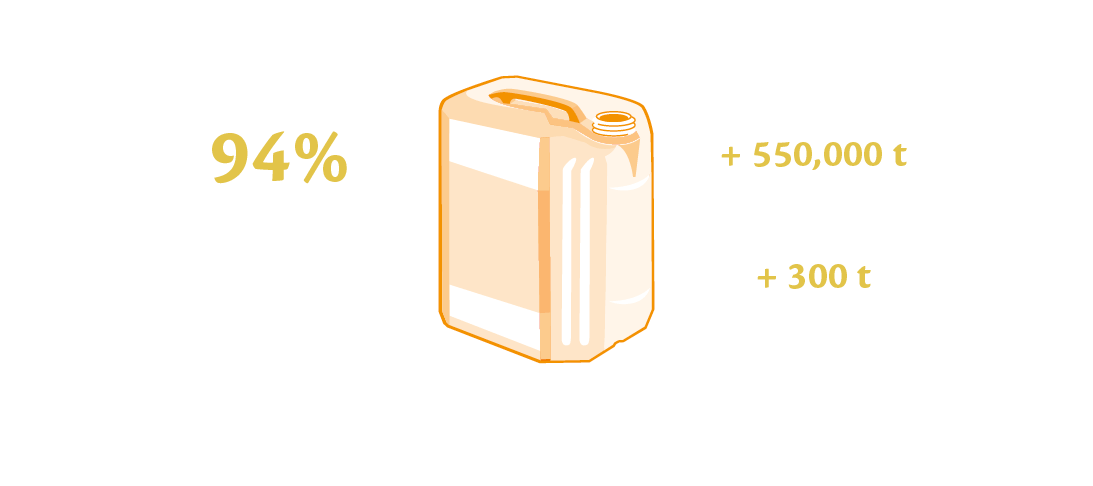

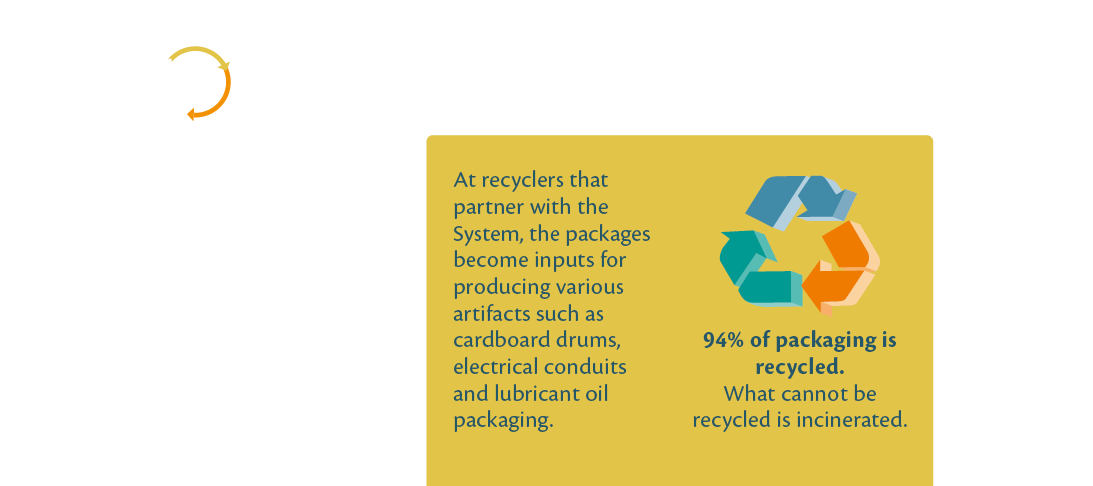

This systemic work is responsible for correctly disposing of 94% of all primary crop protection plastic packaging1sold in the market and has transformed the Campo Limpo System into an efficiency and circular economy reference (read more on this below). Of the total disposed, 94% re-enters the productive process by means of recycling, being transformed into new packages and lids for crop protection products or into other artifacts for the civil construction, automotive and energy industries, among other sectors. The 6% of material that cannot be recycled is sent to incineration.

107

Receiving central offices

304

Outposts

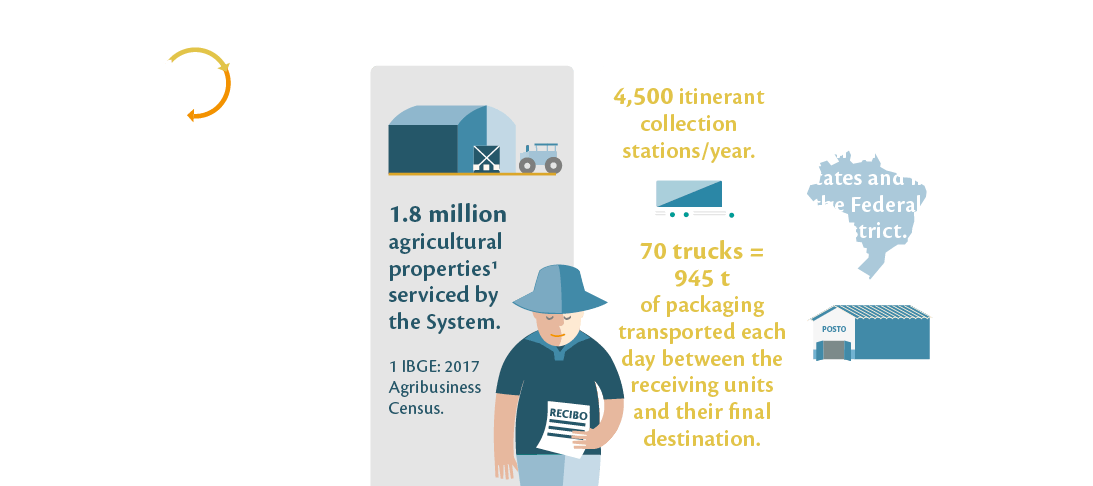

4,500

Itinerant collection stations

Present in all states of Brazil and in its Federal District, the Campo Limpo System relies on more than 400 fixed units (outposts and receiving stations), besides conducting around 4,500 itinerant collection stations in 2019.

1 - Primary packages are those that are in contact with the product.

What is Campo Limpo System?

Click to enlarge

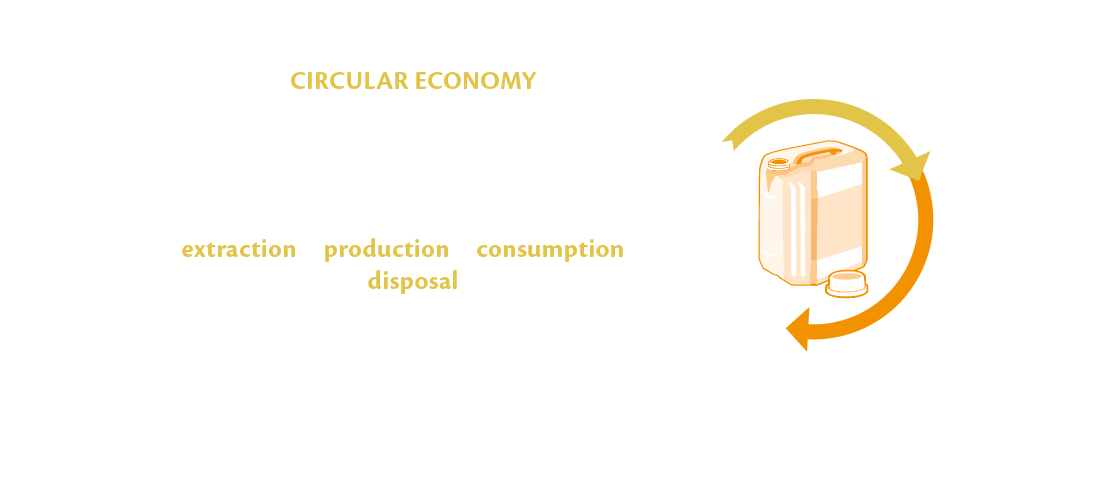

CIRCULAR ECONOMY

Produced using recycled high density polyethylene, it consists of three layers, the first inner one of new resin and the others of recycled material. It offers high performance and safety with UN certification (group II, density 1.4 g/cm3) for land and sea transportation of hazardous products. Produced using polypropylene and polyethylene, Ecocap® is 100% recycled, easy to handle and offers high safety performance.

A circular economy seeks new ways of designing, producing and consuming, by respecting the limits of the planet and generating value. This is a systemic change, including concerns with the product life-cycle since its development and guaranteed return of these materials to the productive process, thus increasing the usage and re-usage capacity of goods and natural resources to maximum productivity, by keeping them in the economy and generating value. These residues become once again raw material for their own production (also known as closed cycle) or their components are sent to other industrial segments (the so-called second life of an input). This is the model that inspires the Campo Limpo System.

A reference in the circular process

Conceived by inpEV, the Campo Limpo Plastic Transformation and Recycling S.A. is responsible for an important technological evolution: the first primary packaging of crop protection products manufactured using resin recycled from post-consumption packaging of this same product. The only one of its kind in the world, Ecoplástica® offers high performance and safety. Campo Limpo Tampas e Resinas Plásticas Ltda. produces a high performance sealing system known as Ecocap®. Together, Ecoplástica® and Ecocap® offer a complete solution and allow the packaging management cycle to be closed within the chain itself. The profit from these companies is reinvested to cover the System costs.

The resins from empty crop protection packaging are also sent to other recycling partners, responsible for inserting this material into artifacts used by the civil construction, automotive and energy industries, among other sectors. Corrugated ducts, sewage pipes, construction blocks, signposts and drums are some of the artifacts produced in a process designed to reduce the demand for new natural resources.

SHARED RESPONSIBILITY

Click on the icons to learn more

they must indicate the proper return locations to receive and store the empty packaging and indicate them on the bill of sale, as well as supply proof of return to the farmer upon packaging receipt; together with the other links, they must educate farmers and develop their awareness on the importance of following the correct procedures and participate in reverse logistics.

FLOW OF THE CAMPO LIMPO SYSTEM

MANAGEMENT OF THE RECEIVING UNITS

The empty packaging receiving system has 411 units throughout the country. The structure consists of 304 outposts and 107 central stations that receive, segregate and prepare (compression, bailing and bagging) the materials for the most adequate final disposal - recycling or incineration. Itinerant collection stations increase the capillarity of the System, offering alternatives for farmers to return their empty packaging. The fixed receiving stations are managed by the distribution channel, which can be a sales association or an agricultural cooperative, or by inpEV, which had 29 central stations under its management by the end of 2019.

Besides its scope and guaranteeing different forms of receiving, the Campo Limpo System is constantly evolving to stay in pace with the dynamics of Brazilian agribusiness and ensure proper waste management. Part of this process consists of inpEV incorporating the management of receiving stations. This topic was discussed by the Board of Directors with the participation of all links of the agricultural chain which, under a system view, seeks a centralized management model for these units.

Central stations

units that receive, separate and process the empty packages to be sent to a proper destination.

Outposts

these are smaller structures than the central stations, capable of receiving the empty packages and separating them, then sending them to the central stations.

Itinerant collection stations

moving units for the temporary receipt of empty containers in more distant regions from the fixed receiving units.

Scheduled return of empty packages (adEV)an electronic system that allows farmers to schedule the return of empty packages or those containing leftovers.

As the managing entity of the System, inpEV has the knowledge of the entire packaging disposal process and disseminates good practices on topics such as environmental management, promotion of a safe and efficient working environment at the central stations. This experience, coupled with the management the Institute already conducted of six central stations until 2018, demonstrated the gain opportunities of more integrated management. The purpose is for this measure to bring benefits to the entire Campo Limpo System, including advances in efficiency with process standardization and a consequent cost reduction for all links of the chain.

In 2019, 23 central stations were incorporated under the Institute’s management in a transition process that sought to enhance dialog and articulation. As a principle, the workers of these stations became inpEV employees, thus leveraging the technical know-how already incorporated at these units. Along the year, training sessions and meetings sought to align the practices of the units and promote integration among inpEV professionals and the recently-incorporated central stations (read more in Human development)

Central station management transfer to the Institute should continue over the next years in a gradual fashion.

EXPANSION

In August, with the participation of governmental representatives, the manufacturing industry and distribution channel, the new facilities of the Campo Limpo Tampas e Resinas Plásticas Ltda. were inaugurated in Taubaté (SP). This industrial complex was expanded, gaining over 4,500 m2 to manufacture Ecocap®, produced from post consumption lids received by the Campo Limpo System. In September, Campo Limpo Plastic Transformation and Recycling S.A., which produces Ecoplástica® (crop protection packaging manufactured using postconsumption packaging originating from the System), inaugurated its new factory in Ribeirão Preto (SP).

DISPOSED PACKAGING GRI 301-3 and 306-2

The year was marked by a record disposal of empty packages, totaling 45,563 tons. This volume represents a 3% increase when compared to 2018 and demonstrates the System’s capacity to keep pace with the agricultural sector growth in the country and the efficiency of this operation. The material was destined in the following fashion: 94% was sent to recycling and 6% to incineration. For 2020, the goal is to handle 46,000 tons of empty packaging.

The System performs the correct disposal of all types of crop protection packaging regularly sold in the market. This includes plastic or metal packaging, its lids and the cardboard boxes used for transportation.

Crop protection post-consumption leftovers that farmers have not completely used are also received. Leftovers can be of two types: expired products or those with damaged packaging that prevent their use; or products no longer used, which registry has been canceled, though not prohibited, and are no longer recommended for use. In 2019, 131 tons of these packages were received and destined by the Campo Limpo System. In this case, this material is exclusively sent to incineration.

Record volume: 45,563 tons of empty packaging disposed in 2019. The goal is to dispose 46,000 tons in 2020.

TOTAL WEIGHT OF RESIDUES, BY TYPE AND METHOD OF DISPOSAL GRI 306-2 | |

|---|---|

Non-hazardous residue (in tons) | 2019 |

Recycling1 | 42,528.2 |

Subtotal of non-hazardous residue | 42,528.2 |

Hazardous residue (in tons) | 2019 |

Recycling1 | 362.7 |

Incineration (mass burning)2 | 2,803.0 |

Subtotal of hazardous residue | 3,165.7 |

Total | 45,693.9 |

1 - Steel, aluminum (packaging and IBC reservoir grating), coextruded polyethylene washed plastic packaging (COEX) and high density polyethylene (HDPE), cardboard and lids, besides rigid unwashed packaging. 2 Flexible unwashed plastic packaging, IBC reservoir bubble, aluminum hydroxide, glass packaging and packaging with solid and liquid postconsumption leftovers.

VOLUME DESTINED BY STATE (KG) | ||

|---|---|---|

Mato Grosso | 11,183,362 | 25% |

Paraná | 5,949,245 | 13% |

São Paulo | 5,026,544 | 11% |

Rio Grande do Sul | 4,826,639 | 11% |

Goiás | 3,856,349 | 8% |

Mato Grosso do Sul | 3,466,210 | 8% |

Minas Gerais | 3,441,204 | 8% |

Bahia | 3,375,985 | 7% |

Santa Catarina | 801,735 | 2% |

Maranhão | 779,621 | 2% |

Others | 2,856,195 | 5% |

Overall Total | 45,563,089 | 100% |